HIGH ACCURACY

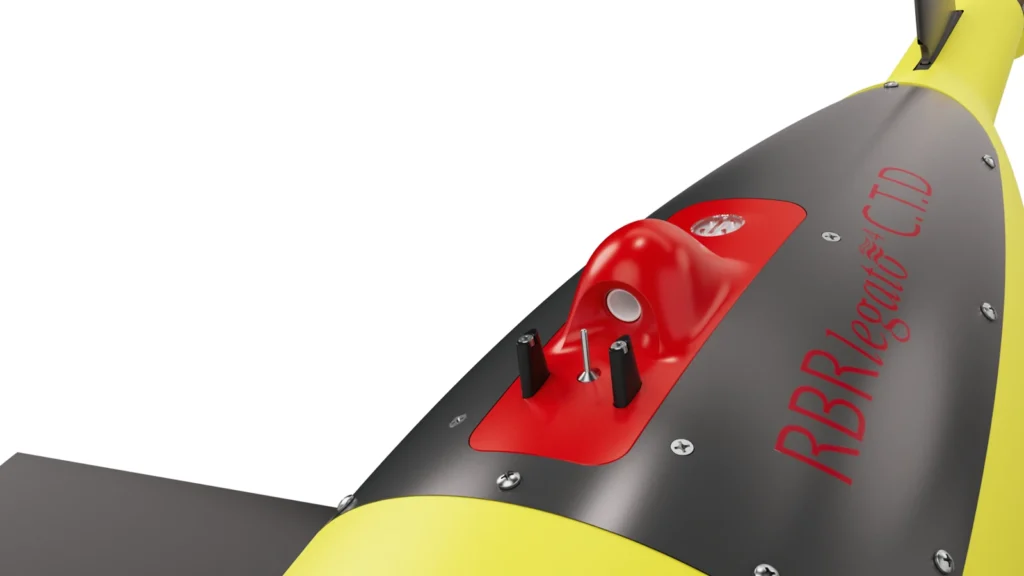

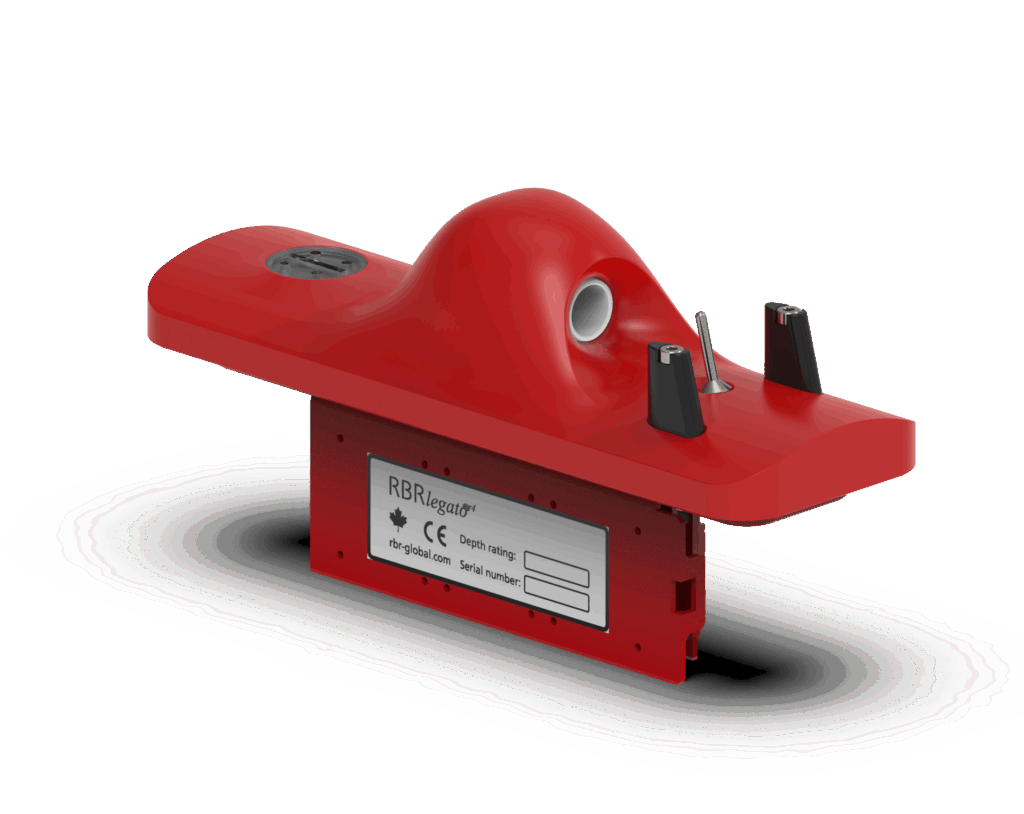

RBRlegato4 C.T.D

Multi-channel instrument for gliders and AUVs

The RBRlegato4 C.T.D offers a new world of measurement opportunities for gliders and AUVs. Optimised for flow dynamics, the instrument requires no pump to obtain fine structure measurements. The RBRlegato4 provides high accuracy while consuming less power due to modern electronic design and the lack of moving parts.

- Rated to 1250dbar

- Pump-free design with optimized flow dynamics

- Ultra-low power consumption

- Multi-rate sampling up to 16Hz

- Accurate conductivity to within 10cm of the air-ocean interface

- Unaffected by surface contaminants or freezing conditions

Features

Legato means smooth and connected. The RBRlegato4 design and low-power operation is optimized for gliders and AUVs. The CTD is used to derive salinity, density, and sound velocity. The RBRlegato4 measures conductivity using a rugged inductive cell that is not affected by surface contaminants or freezing conditions. The CFD-optimised, low aspect ratio conductivity cell is self-flushing and does not require a pump. Using only 46mW when sampling at 2Hz or faster, and 18mJ/sample at 1Hz or slower, the power requirement is 90% lower than traditional pumped CTD sensors. When power management is critical to your mission, the lower power operation permits substantially longer deployments or higher resolution measurements. Totally silent operation is optimized for passive acoustic listening and turbulence measurements. The RBRlegato4 is designed to fit into a standard 2″ x 7″ sensor bay and is rated to 1250m.

The RBRlegato4 can seamlessly integrate and control your additional sensors. Using the standard RBR building-block system architecture, additional sensors such as dissolved oxygen, fluorescence, turbidity, and PAR are all supported. This sensor-hub design permits efficient system integration for vehicle integrators and users.

About the sensors

Conductivity is measured with an inductive sensor, suitable for deployment in marine, estuarine, or fresh water. There are no exposed contacts, which increases robustness, avoids susceptibility to surface contamination, and allows it to be frozen into ice without damage.

The temperature sensor is built and calibrated in-house using an aged thermistor. The temperature channel is calibrated an accuracy of ± 0.002°C (ITS-90) over the range -5 to +35°C. Extended range calibrations are available.

Pressure is measured with a piezoresistive transducer built with a nickel-based superalloy diaphragm to avoid corrosion. Accuracy is 0.01% of the full scale rating and resolution is 0.001%.

Optional configurations

| Design integration | For installation in dry sensor bays |

|---|---|

| Available sensors | Conductivity (C), Temperature (T), Pressure (D), Optical Dissolved Oxygen (ODO), Photosynthetically Active Radiation (PAR), Radiometer (rad), Turbidity (Tu), Backscatter (bb), Chlorophyll a, Fluorescence (Fl), pH |

Specifications

| Storage | 240M readings |

|---|---|

| External power | 4.5-30V |

| Communication | RS-232 |

| Clock drift | ±60 seconds/year |

| Depth rating | 1250m |

| Housing | OSP |

| Length | 195.8mm |

| Width | 63.8mm |

| Height | 78.6mm |

| Top Curvature | ⌀220mm or ⌀124mm |

| Weight | ~0.8kg in air ~0.2kg in water |

| Sampling speed | Up to 2Hz (16Hz optional) |

| Range | 0-85mS/cm |

|---|---|

| Initial accuracy | ±0.003mS/cm |

| Typical stability | 0.010mS/cm/year |

| Resolution | 0.0001mS/cm |

| Range | -5°C to 42°C |

|---|---|

| Initial accuracy | ±0.002° (-5 to +35 °C) |

| ±0.004 °C (+35 to +42 °C) | |

| Resolution | <0.00005°C |

| Time constant | <1s (standard) or <0.1s (|fast16) |

| Typical stability | 0.002°C/year |

| Operating temperature | -5°C to 35°C |

| Range | 1250dbar |

|---|---|

| Initial accuracy | ±0.01% full scale |

| Resolution | 0.001% full scale |

| Time constant | <0.01s |

| Typical stability | 0.01% FS |

| ≤1Hz sampling | 22.8mJ per sample |

|---|---|

| ≥2Hz sampling | 46mW |

| Sleep power | 180µW |